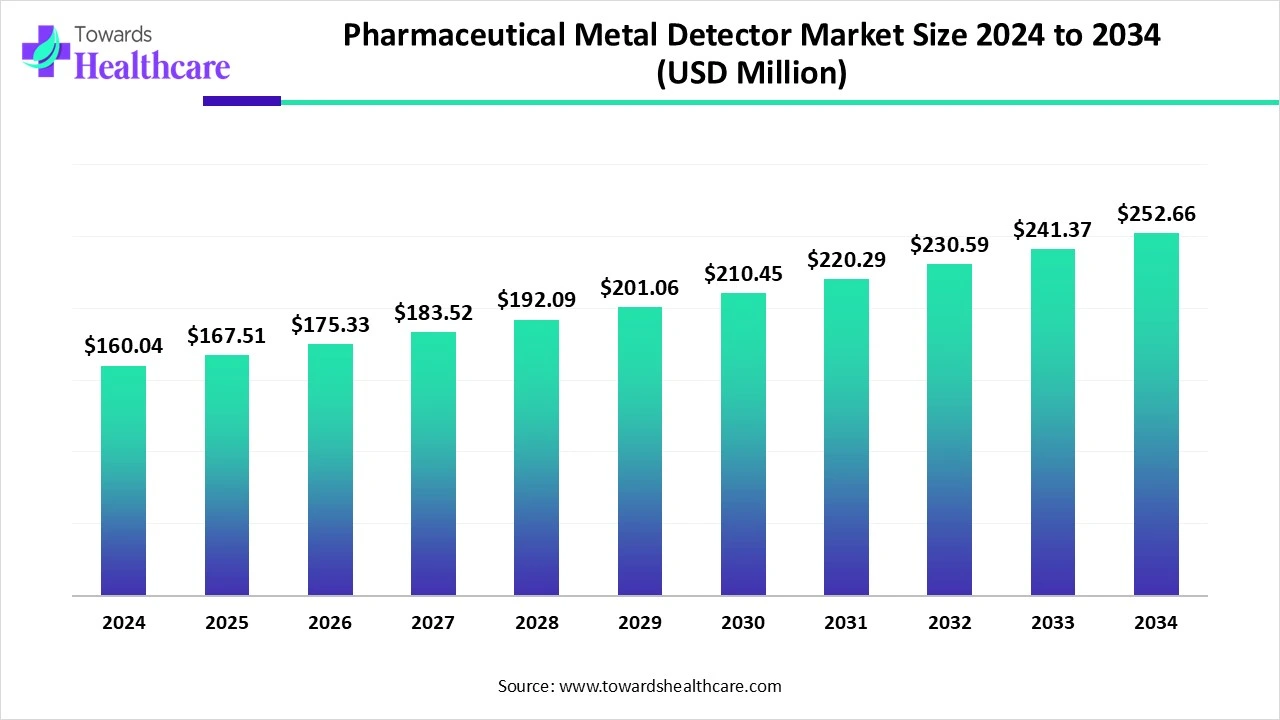

The global pharmaceutical metal detector market is valued at USD 160.04 million in 2024 and is projected to reach USD 167.51 million in 2025, growing steadily at a CAGR of 4.67% (2025–2034) to achieve USD 252.66 million by 2034.

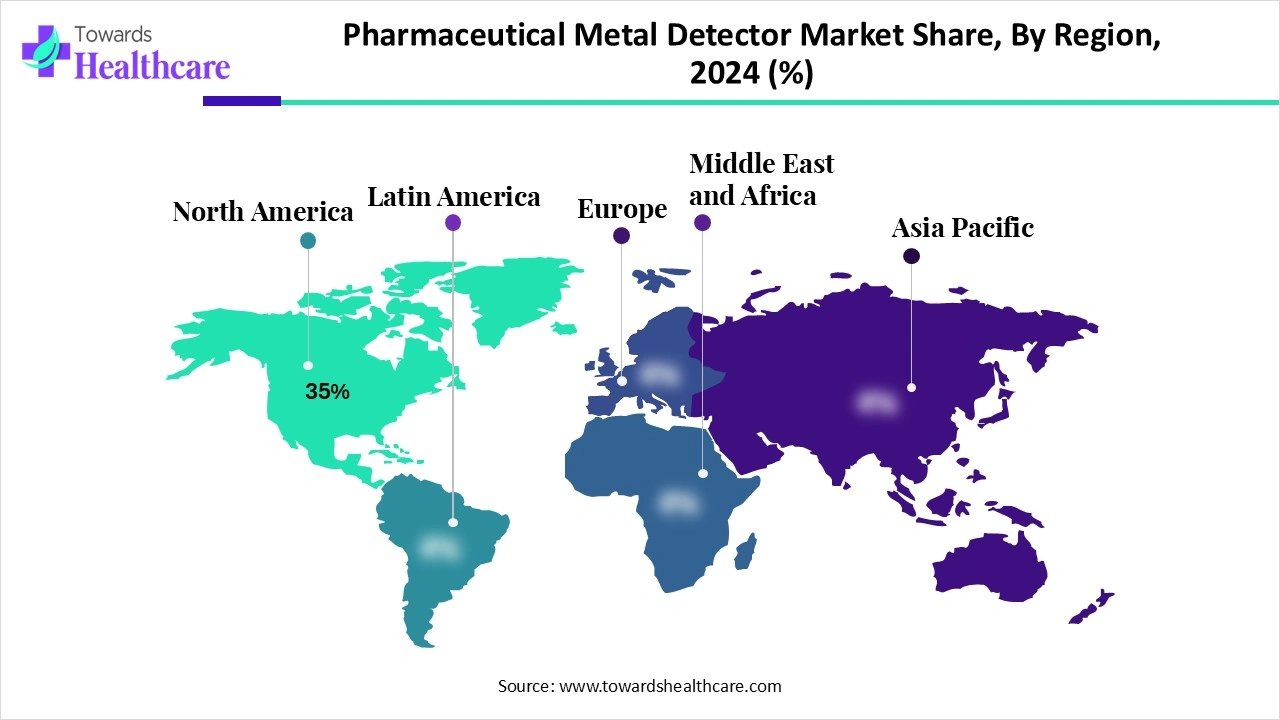

This growth is fueled by rising pharmaceutical production volumes, stringent quality & safety regulations, and the adoption of advanced detection technologies. North America dominates with ~35% share in 2024, while Asia Pacific emerges as the fastest-growing region. Integrated systems (~45% share in 2024) lead the market, while standalone detectors show the fastest growth ahead.

Download the free sample and get the complete insights and forecasts report on this market @ https://www.towardshealthcare.com/download-sample/6035

Market Size

◉2024 Market Size: USD 160.04 million

◉2025 Market Size: USD 167.51 million

◉2034 Market Size (Projected): USD 252.66 million

◉CAGR (2025–2034): 4.67%

Regional Contribution:

◉North America: ~35% share (2024)

◉Asia Pacific: fastest CAGR (2025–2034)

By Product Type (2024 shares):

◉Integrated Systems → 45% (largest segment)

◉Standalone → Fastest growth (2025–2034)

By Technology (2024 shares):

◉Electromagnetic Induction → 50% (largest)

◉X-ray → Fastest CAGR (2025–2034)

By Contaminant Type (2024 shares):

◉Ferrous → 40% (largest)

◉Stainless Steel → Fastest CAGR (2025–2034)

By End-Use (2024 shares):

◉Pharmaceutical Manufacturing Plants → 55% (largest)

◉Biotechnology Companies → Fastest CAGR (2025–2034)

Market Trends

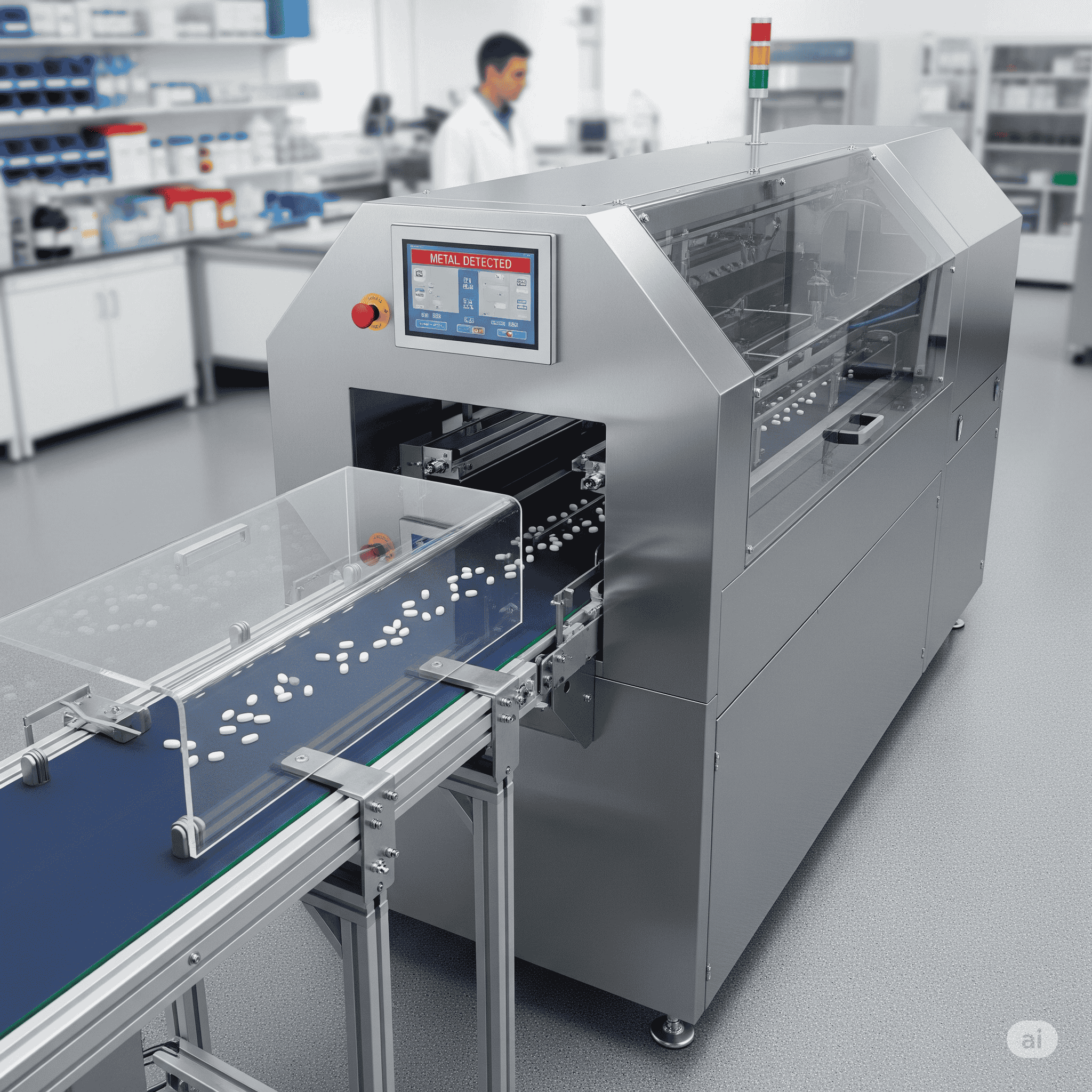

Rising Adoption of Integrated Metal Detection Systems

◉Integrated systems (metal detection + weighing/X-ray combo) dominate.

◉Helps reduce downtime and enhances overall production efficiency.

◉Shift Towards Next-Generation Detection Systems

◉April 2025 – Loma Systems launched IQ4M Metal Detector in North America.

◉Features high accuracy, minimized false rejects, and future-ready design.

AI & Smart Metal Detection

◉Increasing integration of AI and deep learning into detection systems.

◉July 2025 – Agilent Technologies launched InfinityLab Pro iQ Series in India.

◉Enables trace-level contaminant detection, impurity profiling, and biomolecule analysis.

Multi-Frequency Detection Advances

◉New multi-coil arrangements improve detection by 20% compared to single frequency systems.

◉Enables better detection across different densities and packaging formats.

Regulatory Push Driving Adoption

◉FDA, EMA, and international compliance standards ensure mandatory safety checks.

◉Especially crucial for export-oriented pharma manufacturers.

Role of AI in Pharmaceutical Metal Detector Market

AI-Powered Detection Precision

◉Deep learning algorithms classify ferrous, non-ferrous, stainless steel contaminants more accurately.

◉Eliminates false positives → reduces product waste.

Real-Time Monitoring & Predictive Analytics

◉AI-enabled detectors predict possible machine failures and downtime.

◉Ensures continuous production without interruptions.

Worker & Consumer Safety

◉AI-driven detectors instantly alert operators in case of hazardous metal presence.

◉Prevents contaminated products from reaching consumers.

Efficiency Gains

◉AI reduces need for manual inspection, lowering cost of ownership.

◉Enables automated reject systems, improving speed of pharma production.

AI in Advanced Hybrid Systems

◉AI combines X-ray + electromagnetic induction + data analysis for multi-level security.

◉Detects even nano-sized metal particles in tablets, capsules, and syrups.

Future Role

◉AI to integrate with cloud-based data monitoring → global pharma plants share real-time safety data.

◉Predictive defect analysis will drive next-gen compliance management.